What is a Wire Stripping Machine and How Does It Work?

Introduction

Wire stripping is a crucial process used in a variety of industries, from recycling to electrical work. The ability to remove insulation from wires efficiently and accurately can make all the difference in both production speed and safety. But how do industries handle this task on such a large scale? The answer is simple: wire stripping machines. These machines automate the process, making it faster, safer, and more effective. But what exactly is a wire stripping machine, and how does it work?

In this post, we’ll explore the different types of wire stripping machines, how they operate, and why they are essential tools for anyone working with electrical wiring or involved in wire recycling.

What is a Wire Stripping Machine?

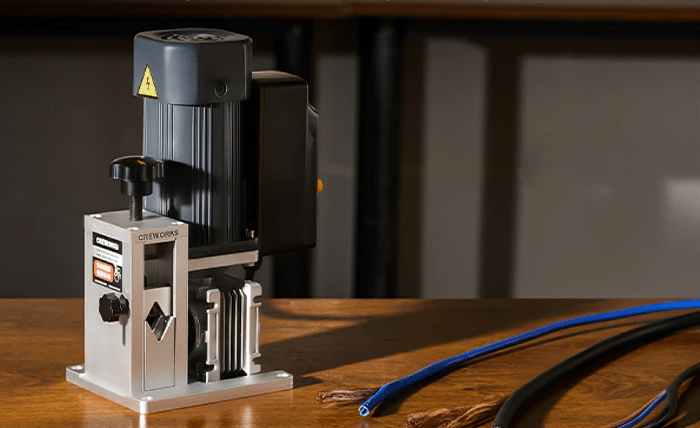

A wire stripping machine is a specialized device designed to remove the insulation from electrical wires. This process exposes the bare wire underneath, which is necessary for many tasks such as connecting wires to electrical components or recycling copper wire.

Wire stripping machines come in various sizes and capabilities, from small, manual models used in DIY projects to large, industrial machines that handle high volumes of wire. The machine works by gripping the wire and cutting or scoring the insulation, then pulling or twisting it off to reveal the metal underneath.

The importance of this machine cannot be overstated—whether for recycling scrap wire or preparing wires for electrical installations, wire stripping machines provide a fast, clean, and efficient solution.

Types of Wire Stripping Machines

Wire stripping machines come in different types, each suited to various needs and environments. The three main types are:

- Manual Wire Stripping Machines: These are basic machines that require the user to manually feed the wire into the machine. They are perfect for DIYers and small-scale operations that don’t need to strip large amounts of wire.

- Semi-Automatic Wire Stripping Machines: These machines offer a blend of automation and manual input. The user still needs to feed the wire in, but the machine takes care of most of the stripping process. They are ideal for medium-scale operations or businesses that handle a moderate volume of wire.

- Fully Automatic Wire Stripping Machines: These are the most advanced machines, capable of automatically feeding, stripping, and cutting wire without any manual intervention. They are used in high-volume industries, such as manufacturing and large-scale recycling operations.

Components of a Wire Stripping Machine

Wire stripping machines come with several key components that work together to make the wire stripping process efficient:

- Blades and Cutters: These are the main parts that cut or score the insulation to remove it. Depending on the machine, blades may be adjustable to handle different wire sizes and types of insulation.

- Rollers: These help grip the wire and pull it through the machine, ensuring the stripping process is smooth and even.

- Motor or Manual Mechanism: In automatic and semi-automatic machines, a motor powers the machine’s operations. In manual machines, the user typically turns a crank or lever to feed the wire.

- Adjustable Settings: Many machines allow you to adjust the speed, pressure, and blade position to ensure the proper stripping of various wire gauges.

How Does a Wire Stripping Machine Work?

Using a wire stripping machine is relatively simple but requires careful attention to detail. Here’s a step-by-step breakdown of how most machines operate:

- Inserting the Wire: First, the wire is inserted into the machine, either manually or automatically, depending on the machine’s type.

- Cutting/Scoring the Insulation: The machine’s blades or cutting wheels score the insulation, creating a clean cut along the length of the wire.

- Stripping the Insulation: Once the insulation is cut, the machine uses rollers or other mechanisms to pull the insulation off, revealing the copper or metal wire underneath.

- Adjusting for Precision: For different wire gauges or insulation types, the machine settings may need to be adjusted to ensure precise stripping without damaging the wire.

The efficiency of this process is what sets wire stripping machines apart from manual stripping, where human error and inconsistent results are more likely.

Applications of Wire Stripping Machines

Wire stripping machines are invaluable in a variety of industries, including:

- Recycling: These machines are especially useful for recycling copper and other valuable metals. By stripping the wire, the machine allows the metal to be processed and reused in new products, reducing waste and conserving resources.

- Manufacturing: In large-scale manufacturing, wire stripping machines ensure that wires are prepared quickly and accurately for assembly into electrical devices or equipment.

- Electrical Work: For electricians, wire stripping machines can save time and reduce the risk of cutting or damaging wires when preparing them for installations or repairs.

- DIY Projects: Hobbyists and small businesses involved in custom electrical work can use wire stripping machines to handle smaller jobs, ensuring precision without the labor of manual stripping.

Benefits of Using a Wire Stripping Machine

Investing in a wire stripping machine brings numerous benefits, including:

- Efficiency: Wire stripping machines dramatically speed up the process compared to doing it by hand.

- Cost-Effectiveness: While these machines may have an initial cost, they save money in the long run by reducing labor costs and improving efficiency.

- Safety: Using a machine reduces the risk of injury, as manual wire stripping can be dangerous due to sharp tools or handling heated wire.

- Environmental Impact: Machines help streamline wire recycling, making it easier to reclaim valuable metals like copper, which can then be reused, reducing waste.

Choosing the Right Wire Stripping Machine

When selecting a wire stripping machine, there are several factors to consider:

- Wire Size and Gauge: Some machines are better suited for certain wire sizes. Ensure the machine you choose can handle the range of wire you plan to strip.

- Volume of Wire: If you’re working with a high volume of wire, an automatic machine may be the best choice. For smaller projects, a manual or semi-automatic machine might suffice.

- Durability and Power Source: Consider how long you expect to use the machine and whether you need a machine that operates manually or requires electricity. Automatic machines tend to be more durable and efficient but also come at a higher price.

- Budget: While it’s tempting to go for the cheapest option, investing in a quality machine will save you time and money in the long run.

If you’re looking for reliable and efficient wire stripping machines, consider Creworks wire stripping machines. They offer a range of models that cater to different needs, from small-scale operations to high-volume industrial applications. Whether you’re a DIYer or a business, Creworks provides durable and easy-to-use machines that ensure precision and efficiency.

Conclusion

Wire stripping machines play a pivotal role in many industries by making the process of removing wire insulation quicker, safer, and more accurate. From small-scale DIY projects to large industrial operations, these machines offer an indispensable solution for anyone working with electrical wiring or involved in wire recycling. Whether you choose a manual model for small tasks or an automatic machine for high-volume production, investing in a wire stripping machine can save you time, reduce labor costs, and increase overall efficiency. Be sure to choose a machine that suits your specific needs, and consider trusted brands like Creworks for reliable and well-built machines designed for a variety of applications.